Integral Spiral Blade Stabilizer Drilling Stabilizer

CLICK ENLARGE

A downhole stabilizer is a piece of downhole equipment used in the bottom hole assembly (BHA) of a drill string. It mechanically stabilizes the BHA in the borehole in order to avoid unintentional sidetracking, vibrations, and ensure the quality of the hole being drilled.It is composed of a hollow cylindrical body and stabilizing blades, both made of high-strength steel. The blades can be either straight or spiralled, and are hardfaced for wear resistance.

There are mainly three types of drilling stabilizers used in the oilfield today.

1. Integral stabilizer, which is fully machined out of a single piece of steel. This type tend to be norm and widely used.

2. Replaceable sleeve stabilizer, where the blades are located on a sleeve, which is then screwed on the body. This type can be economical when no repair facilities are available close to the well being drilled.

3. Welded blades stabilizer, where blades are welded onto the body. This type is usually not advised on oil wells due to the risks of losing blades, but is regularly used when drilling water wells or on low-cost oilfields.

Usually 2 to 3 stabilizers are fitted into the BHA, including one just above the drill bit (near-bit stabilizer) and one or two among the drill collars (string stabilizers).

Description:

PLATO a complete line of downhole drilling stabilizers to increase the rate of penetration and control hole deviation problems. All these stabilizers (including drill bit type, drill string type, spiral blade, straight blade, integral blade, welded blade, sleeve-type, and stainless steel nonmagnetic types) are designed to meet the strictest quality control and quality assurance standards (API SPEC.). All alloy stabilizers are manufactured from AISI 4145H modified heat-treated steel for a wide variety of configurations and hole sizes.

Features:

Sizes and configurations can be manufactured to the operator’s requirements, including blade sizes, connections, and types of material.

All stabilizer connections can be configured as box xbox, as pin x box, or as the operator requires.

Welded straight blade for drilling soft formations.

Sleeve type allowing less equipment inventory in remote locations.

Integral spiral blade allowing 360° hole contact for use in hard rock formations.

Nonmagnetic stabilizers for applications requiring magnetic isolation.

Drawing:

| Drill stabilizer type, in | Working OD, mm | End OD of body, mm | ID, mm | Length, mm | Thread type | |

| Female buckle | Male buckle | |||||

| 6 | 152.2 | 121 | 51 | 1200 | NC38 | 3 1/2 REG |

| 6 1/4 | 158.7 | |||||

| 6 1/2 | 165.1 | |||||

| 7 1/2 | 190.5 | 159 | 57 | 1600 | NC46 | 4 1/2 REG |

| 7 7/8 | 200 | |||||

| 8 3/8 | 212.7 | 159 | 71 | 1600

1800 | NC46

NC50 | |

| 165 | ||||||

| 8 1/2 | 215.2 | 159 165 178 | ||||

| 8 3/4 | 222.2 | |||||

| 9 1/2 | 241.3 | 178 197 | 1600 | NC50 | ||

| 9 5/8 | 344.5 | 1800 | 6 5/8 REG | |||

| 9 7/8 | 250.8 | |||||

| 12 1/4 | 311.1 | 203 209 | 76 | 1800 | NC56 | 6 5/8 REG |

| 6 5/8 REG | ||||||

| 16 | 406 | 229

241.3 | 2000

2200 | NC61

7 5/8 REG | ||

| 17 1/2 | 444.5 | |||||

| 24 | 609.6 | |||||

| 26 | 660.4 | |||||

| 28 | 711.2 | |||||

| Note: Drill stabilizer can be made according to customer’s special requirement. | ||||||

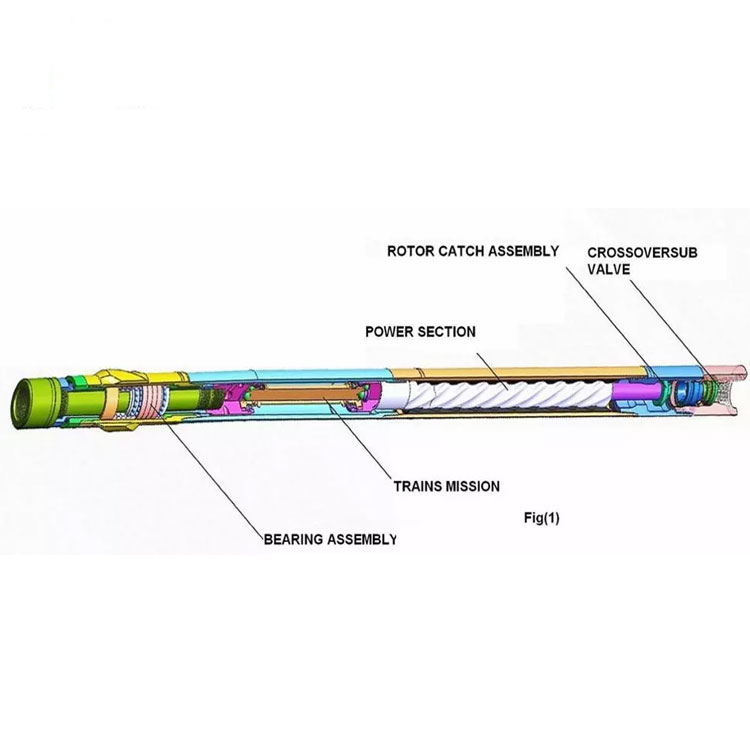

API Drilling Chinese Downhole Drilling Mud Motor is a kind of downhole drilling tool powered by mud. The mud from mud pump enters motor by way of bypass valve, and a pressure drop between motor inlet and outlet created, such pressure drop will drive the motor rotator to rotate, and transmit the torque and rotary speed to bit by universal shaft and transmission shaft. The downhole motor property mainly depends upon its property parameters. This product uses the high and new technology of coating to avoid coating off of rotors resulted from the traditional technology. Its strength and life are greatly improved. It is applicable to Horizontal Directional Drilling, composite drilling, cluster wells, sidetrack wells and well workover, Coiled Tubing Operation, etc. downhole drilling motor

Downhole motor is a type of positive- displacement downhole motor(PDM). After high pressure drilling fluid enters into downhole motor from drill stem, fluid pressure forces rotor to rotate that transfers torque to bit to achieve drilling purpose.

Various downhole motor assemblies for well size 1 7/8"~26" with 24 main dimension specifications (which are identified by outer diameter of stator) : 1-11/16", 2-1/8", 2-3/8", 2-7/8", 3-1/8", 3-1/2", 3-3/4", 4", 4-1/8", 4-3/4", 5", 5-1/4", 5-7/8", 6-1/4", 6-1/2", 6-3/4", 7-1/4", 7-3/4", 8", 8-1/4", 8-1/2", 9", 9-5/8", 11-1/4".

Structure form includes straight, single bend, double bend, angle adjustable and so on. Heat-resistant temperature range consist of 250°F (120℃) or less than 250℉ (120℃), and between 250 ℉(120℃) to 355℉ (180℃). We can also provide all specifications including oil based mud resistant motor and saturated saltwater mud resistant motor.

Outstanding Features

Various rotation rate and torque, high efficiency, wide flow range, smooth operation, easy maintenance, high reliability, long service life.

Safe Application

Adequate strength and specially designed multiple falling-off-proof devices to ensure safe drilling operation.

The ordinary downhole motor consists of the following components:

(1) Float assembly or By-pass valve assembly

(2) Rotor anti-drop assembly

(3) Power section assembly

(4) Universal shaft assembly

(5) Bearing assembly

In addition to ordinary downhole motor, the following components for special purpose are available to make up steerable downhole motor to meet various requirements of drilling operation:

(1) Directional joint

(2) Bend joint (fitted above or below by- pass

valve to make up single or double bend downhole motor)

(3) Hollow by-pass power section

(4) Fixed Bend Housing (with 0~3°fixed angle)

(5) Adjustable bend housing

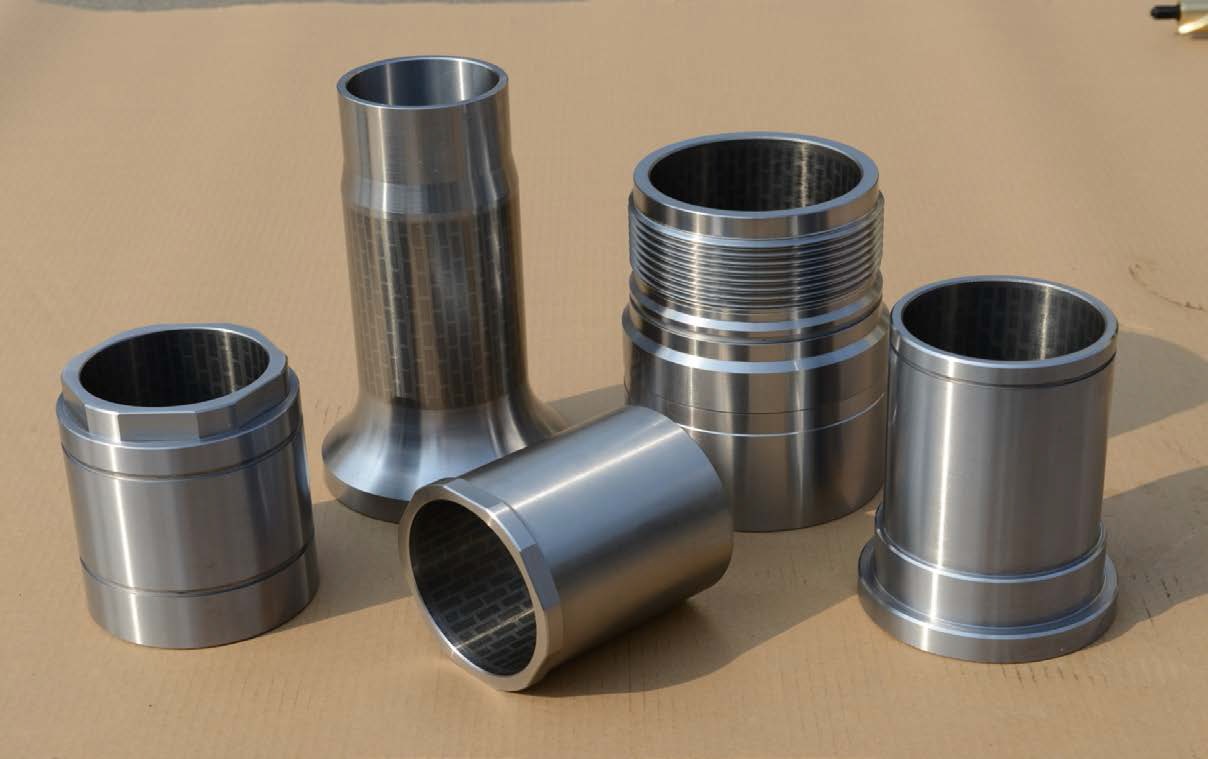

(6) Housing stabilizer on bearing assembly

(7) Changeable stabilizer

downhole drilling motor

(Some Models are here for your reference, more models and deatils pls contact us.)

(Of course, customization is also allowable, as long as you can provide detailed drawing, especially some parts like bearings.)

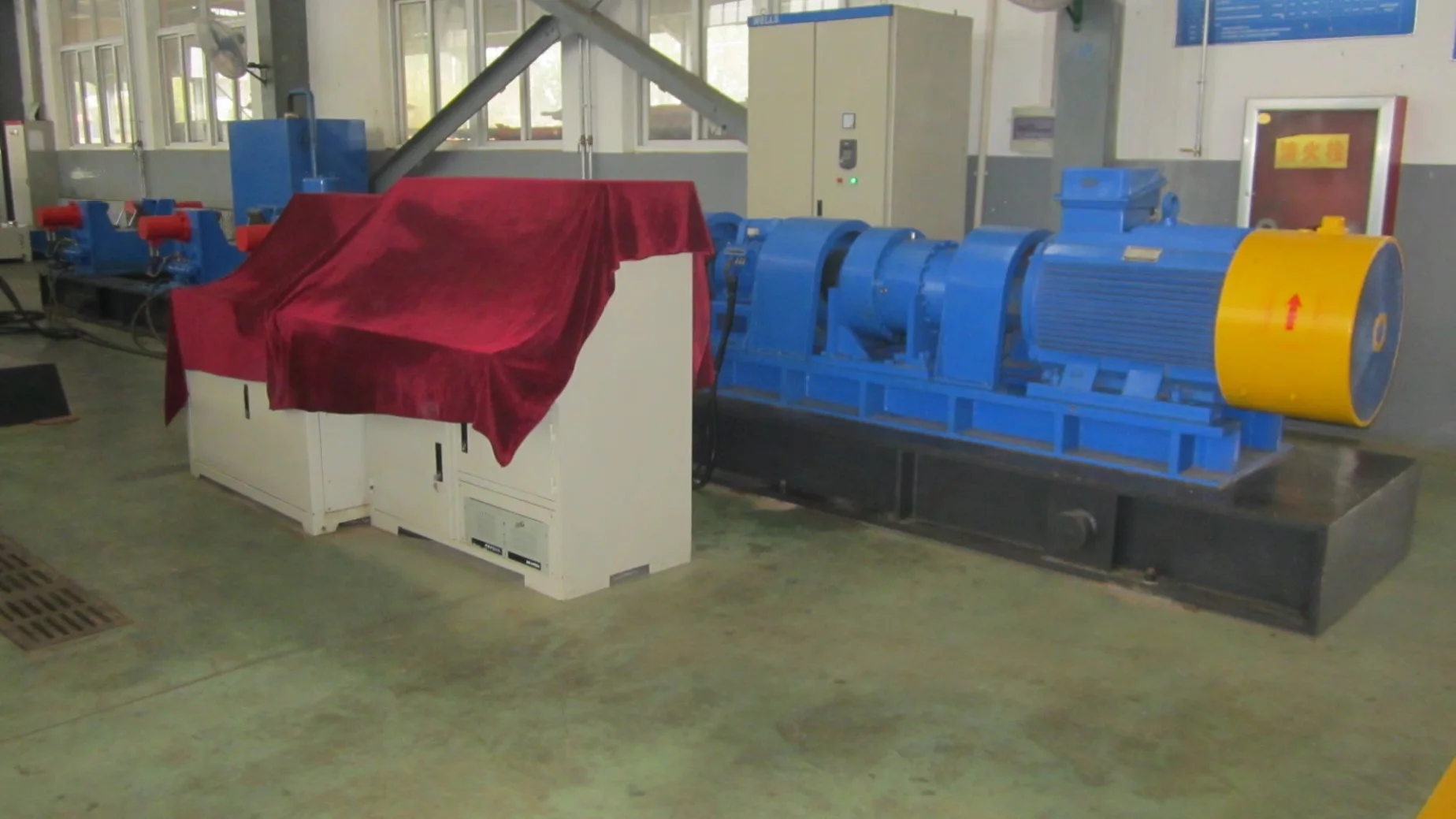

Each downhole mud motor is tested on the professional testing bench and the delivered downhole mud motor is 100% guarateed qualitified, then the test report will be provided to you.

Each downhole mud motor can continuously work 7~10 days with good working condition and correct operation.

Of course, online after-sale service is also available at any time.

Type | 5LZ73 7.0 | 5LZ89 7.0 | 5LZ95 7.0 | 7LZ95 3.5 | 9LZ95 7.0 | 5LZ120 7.0 | |

Hole Size | Mm | 95~121 | 114~152 | 118~152 | 118~152 | 118~152 | 149~200 |

In | 33/4~43/4 | 41/2~6 | 45/8~6 | 45/8~6 | 45/8~6 | 57/8~77/8 | |

Thread Type | Top | 23/8"REG | 23/8"REG | 27/8"REG | 27/8"TBG | 27/8"REG | 31/2"REG |

Bottom | 23/8"REG | 23/8"REG | 27/8"REG | 27/8"REG | 27/8"REG | 31/2"REG | |

Nozzle pressure drop | Mpa | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~3.5 | 1.4~7 | 1.4~7 |

Recommend Flow | L/S | 3~8 | 3~8 | 7~12 | 7~11 | 6~10 | 9~14 |

Bit rotary | R/Min | 109~291 | 95~200 | 90~195 | 120~240 | 90~200 | 95~200 |

Motor pressure drop | Mpa | 2.4 | 2.4 | 3.2 | 2.4 | 2.4 | 3.2 |

Working torque | N.M | 460 | 628~838 | 1260~1630 | 723~960 | 750~1020 | 1480~1820 |

Lagging torque | N.M | 650 | 1300 | 2200 | 1500 | 1550 | 2440 |

Output power | KW | 4.7~12.5 | 7.3~15.3 | 13.6~29.5 | 18~24 | 8.3~18.5 | 16.4~34.5 |

Recommended bit weight | T | 4.7~12.5 | 2.0 | 2.5 | 1.0 | 2.5 | 3 |

Max bit weight | T | 2.5 | 3.0 | 5 | 1.5 | 5 | 5 |

Length | Straight | 3450 | 3570 | 4450 | 2500 | 3590 | 5085 |

Single curve | 3450 | 4675 | 3590 | 5335 | |||

Weight | Straight | 100 | 98 | 140 | 89 | 120 | 390 |

Single curve | 102 | 150 | 120 | 420 | |||

Type | 5LZ165 7.0 | 5LZ165 7.0 | 5LZ172 7.0 | 5LZ197 7.0 | 5LZ210 7.0 | 5LZ244 7.0 | |

Hole Size | Mm | 213~251 | 213~251 | 213~251 | 251~311 | 251~375 | 311~445 |

In | 83/8~97/8 | 83/8~97/8 | 83/8~97/8 | 97/8~121/4 | 97/8~143/4 | 121/4~171/4 | |

Thread type | Top | 41/2"REG | 41/2"REG | 41/2"REG | 51/2"REG | 65/8"REG | 65/8"REG |

Bottom | 41/2"REG | 41/2"REG | 41/2"REG | 65/8"REG | 65/8"REG | 75/8"REG | |

Nozzle pressure drop | Mpa | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~7 |

Recommend Flow | L/s | 20~28 | 20~28 | 25~35 | 25~57 | 35~50 | 50~75 |

Bit rotary | R/min | 90~160 | 80~150 | 90~160 | 86~196 | 100~160 | 100~160 |

Motor pressure drop | Mpa | 2.4 | 3.2 | 4.0 | 4.0 | 4.0 | 4.0 |

Working torque | N.m | 2750~3960 | 3860~4980 | 5860~6970 | 7800~9350 | 9980~11900 | 12870~13970 |

Lagging torque | N.m | 6300 | 8470 | 11550 | 18690 | 19600 | 23000 |

Output power | Kw | 31.6~56.2 | 37~69.4 | 60.4~107.4 | 70~160 | 115~183 | 140~225 |

Recommended bit weight | T | 8 | 8 | 10 | 16 | 17 | 18 |

Max bit weight | T | 16 | 16 | 16 | 24 | 28 | 30 |

Length | Straight | 5930 | 6830 | 7230 | 8470 | 8400 | 9060 |

Single curve | 6180 | 7080 | 7480 | 8720 | 8660 | 9320 | |

Weight | Straight | 742 | 820 | 930 | 1140 | 1460 | 1980 |

Single curve | 772 | 850 | 970 | 1195 | 1520 | 2050 | |

Power Section:

Anti-dropping Device

Ball Drive Universal Shaft Assy

ABH Assy

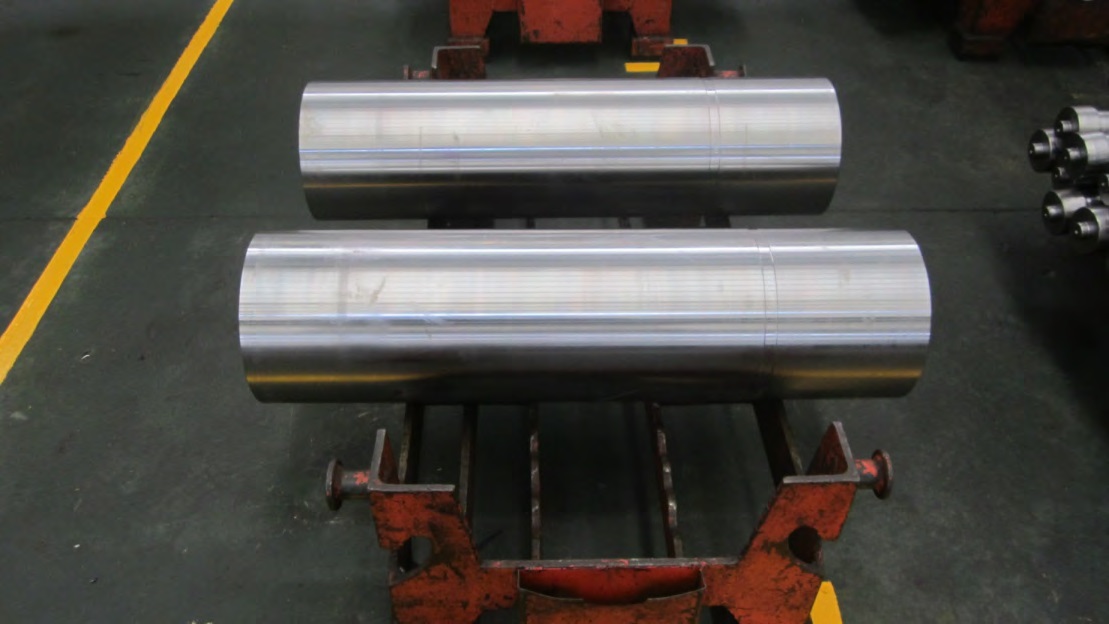

Driveshaft Mandrel Finished TC Radial Bearing

Finished Housing Transmission Shaft Assy

Power Section Testing Bench Downhole Motor Testing Bench

downhole drilling motor downhole drilling motor downhole

Your email address will not be published. Required fields are marked with *