Integral Construction Hydraulic Pressure Whipstock

CLICK ENLARGE

Many oil fields in domestic and foreign has reached the mid-final exploitation stage.The old well recovery and the accident well processing gradually increased.Window sidetracking technology has been widely used as the main method to solve the problem.

The conventional whipstock window cutting need decline whipstock and window cutting two steps, operation complex and cost expensive.The integral construction hydraulic pressure whipstock can complete two steps at one time, greatly shorten the construction period, save the construction cost.

The integral construction hydraulic pressure whipstock has simple operation, sealing strong,short window cutting advantages etc .

The integral construction hydraulic pressure whipstock have two parts: whipstock and window cutting milling taper.

Whipstock

Whipstock adopts hydraulic seat sealing way, strong seat sealing, easy operation. The slant face is cambered surface use hardening treatment, when window cutting, the milling taper highly coincides with the slant face, drilling pressure can be controlled easily, decreased choke off drilling and bit bouncing. Internal adopts special pressure transmission structure, safe and reliable.Tool internal self-locking mechanism will be improved, using the axial and circumferential all-around self-locking, greatly improve the reliability of the tool.Window Cutting Milling Taper

In casing, whipstock and window cutting milling cone matched to finish window cutting work. whipstock and window cutting milling taper with optimized design of tool shape, cutting edge Angle, selection of alloy block, make window cutting and maintenance integrally, improve the construction speed, shorten the construction period.Basic parameters and performance index

| applied pipe | Whipstock | Window Cutting Milling Cone | Adapted deviation | Adapted temperature | Sealing type | |||||

| Outline dimensions | Bevel angle | Bevel length | Arc-like diameter | Outline dimensions | Buckle type | clipping pressure | ||||

| 51/2" (φ139.7) | φ116x3464 | 3.2° | 1900 | φ125 | φ116x540 | 211x230 | 40KN | ≤40° | ≤200℃ | Direct pressure sealing |

| 7" (φ177.8) | φ150x3960 | 3.2° | 2515 | φ165 | φ150x630 | 311x330 | 60KN | |||

| 95/8" (φ244.4) | φ210x4850 | 4° | 2650 | φ225 | φ210x710 | 411x430 | 80KN | |||

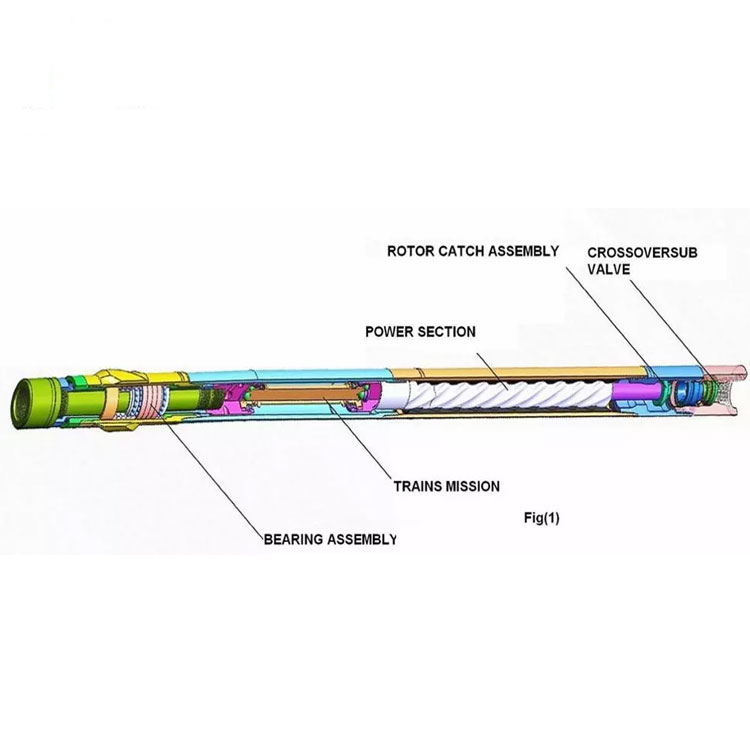

API Drilling Chinese Downhole Drilling Mud Motor is a kind of downhole drilling tool powered by mud. The mud from mud pump enters motor by way of bypass valve, and a pressure drop between motor inlet and outlet created, such pressure drop will drive the motor rotator to rotate, and transmit the torque and rotary speed to bit by universal shaft and transmission shaft. The downhole motor property mainly depends upon its property parameters. This product uses the high and new technology of coating to avoid coating off of rotors resulted from the traditional technology. Its strength and life are greatly improved. It is applicable to Horizontal Directional Drilling, composite drilling, cluster wells, sidetrack wells and well workover, Coiled Tubing Operation, etc. downhole drilling motor

Downhole motor is a type of positive- displacement downhole motor(PDM). After high pressure drilling fluid enters into downhole motor from drill stem, fluid pressure forces rotor to rotate that transfers torque to bit to achieve drilling purpose.

Various downhole motor assemblies for well size 1 7/8"~26" with 24 main dimension specifications (which are identified by outer diameter of stator) : 1-11/16", 2-1/8", 2-3/8", 2-7/8", 3-1/8", 3-1/2", 3-3/4", 4", 4-1/8", 4-3/4", 5", 5-1/4", 5-7/8", 6-1/4", 6-1/2", 6-3/4", 7-1/4", 7-3/4", 8", 8-1/4", 8-1/2", 9", 9-5/8", 11-1/4".

Structure form includes straight, single bend, double bend, angle adjustable and so on. Heat-resistant temperature range consist of 250°F (120℃) or less than 250℉ (120℃), and between 250 ℉(120℃) to 355℉ (180℃). We can also provide all specifications including oil based mud resistant motor and saturated saltwater mud resistant motor.

Outstanding Features

Various rotation rate and torque, high efficiency, wide flow range, smooth operation, easy maintenance, high reliability, long service life.

Safe Application

Adequate strength and specially designed multiple falling-off-proof devices to ensure safe drilling operation.

The ordinary downhole motor consists of the following components:

(1) Float assembly or By-pass valve assembly

(2) Rotor anti-drop assembly

(3) Power section assembly

(4) Universal shaft assembly

(5) Bearing assembly

In addition to ordinary downhole motor, the following components for special purpose are available to make up steerable downhole motor to meet various requirements of drilling operation:

(1) Directional joint

(2) Bend joint (fitted above or below by- pass

valve to make up single or double bend downhole motor)

(3) Hollow by-pass power section

(4) Fixed Bend Housing (with 0~3°fixed angle)

(5) Adjustable bend housing

(6) Housing stabilizer on bearing assembly

(7) Changeable stabilizer

downhole drilling motor

(Some Models are here for your reference, more models and deatils pls contact us.)

(Of course, customization is also allowable, as long as you can provide detailed drawing, especially some parts like bearings.)

Each downhole mud motor is tested on the professional testing bench and the delivered downhole mud motor is 100% guarateed qualitified, then the test report will be provided to you.

Each downhole mud motor can continuously work 7~10 days with good working condition and correct operation.

Of course, online after-sale service is also available at any time.

Type | 5LZ73 7.0 | 5LZ89 7.0 | 5LZ95 7.0 | 7LZ95 3.5 | 9LZ95 7.0 | 5LZ120 7.0 | |

Hole Size | Mm | 95~121 | 114~152 | 118~152 | 118~152 | 118~152 | 149~200 |

In | 33/4~43/4 | 41/2~6 | 45/8~6 | 45/8~6 | 45/8~6 | 57/8~77/8 | |

Thread Type | Top | 23/8"REG | 23/8"REG | 27/8"REG | 27/8"TBG | 27/8"REG | 31/2"REG |

Bottom | 23/8"REG | 23/8"REG | 27/8"REG | 27/8"REG | 27/8"REG | 31/2"REG | |

Nozzle pressure drop | Mpa | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~3.5 | 1.4~7 | 1.4~7 |

Recommend Flow | L/S | 3~8 | 3~8 | 7~12 | 7~11 | 6~10 | 9~14 |

Bit rotary | R/Min | 109~291 | 95~200 | 90~195 | 120~240 | 90~200 | 95~200 |

Motor pressure drop | Mpa | 2.4 | 2.4 | 3.2 | 2.4 | 2.4 | 3.2 |

Working torque | N.M | 460 | 628~838 | 1260~1630 | 723~960 | 750~1020 | 1480~1820 |

Lagging torque | N.M | 650 | 1300 | 2200 | 1500 | 1550 | 2440 |

Output power | KW | 4.7~12.5 | 7.3~15.3 | 13.6~29.5 | 18~24 | 8.3~18.5 | 16.4~34.5 |

Recommended bit weight | T | 4.7~12.5 | 2.0 | 2.5 | 1.0 | 2.5 | 3 |

Max bit weight | T | 2.5 | 3.0 | 5 | 1.5 | 5 | 5 |

Length | Straight | 3450 | 3570 | 4450 | 2500 | 3590 | 5085 |

Single curve | 3450 | 4675 | 3590 | 5335 | |||

Weight | Straight | 100 | 98 | 140 | 89 | 120 | 390 |

Single curve | 102 | 150 | 120 | 420 | |||

Type | 5LZ165 7.0 | 5LZ165 7.0 | 5LZ172 7.0 | 5LZ197 7.0 | 5LZ210 7.0 | 5LZ244 7.0 | |

Hole Size | Mm | 213~251 | 213~251 | 213~251 | 251~311 | 251~375 | 311~445 |

In | 83/8~97/8 | 83/8~97/8 | 83/8~97/8 | 97/8~121/4 | 97/8~143/4 | 121/4~171/4 | |

Thread type | Top | 41/2"REG | 41/2"REG | 41/2"REG | 51/2"REG | 65/8"REG | 65/8"REG |

Bottom | 41/2"REG | 41/2"REG | 41/2"REG | 65/8"REG | 65/8"REG | 75/8"REG | |

Nozzle pressure drop | Mpa | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~7 |

Recommend Flow | L/s | 20~28 | 20~28 | 25~35 | 25~57 | 35~50 | 50~75 |

Bit rotary | R/min | 90~160 | 80~150 | 90~160 | 86~196 | 100~160 | 100~160 |

Motor pressure drop | Mpa | 2.4 | 3.2 | 4.0 | 4.0 | 4.0 | 4.0 |

Working torque | N.m | 2750~3960 | 3860~4980 | 5860~6970 | 7800~9350 | 9980~11900 | 12870~13970 |

Lagging torque | N.m | 6300 | 8470 | 11550 | 18690 | 19600 | 23000 |

Output power | Kw | 31.6~56.2 | 37~69.4 | 60.4~107.4 | 70~160 | 115~183 | 140~225 |

Recommended bit weight | T | 8 | 8 | 10 | 16 | 17 | 18 |

Max bit weight | T | 16 | 16 | 16 | 24 | 28 | 30 |

Length | Straight | 5930 | 6830 | 7230 | 8470 | 8400 | 9060 |

Single curve | 6180 | 7080 | 7480 | 8720 | 8660 | 9320 | |

Weight | Straight | 742 | 820 | 930 | 1140 | 1460 | 1980 |

Single curve | 772 | 850 | 970 | 1195 | 1520 | 2050 | |

Power Section:

Anti-dropping Device

Ball Drive Universal Shaft Assy

ABH Assy

Driveshaft Mandrel Finished TC Radial Bearing

Finished Housing Transmission Shaft Assy

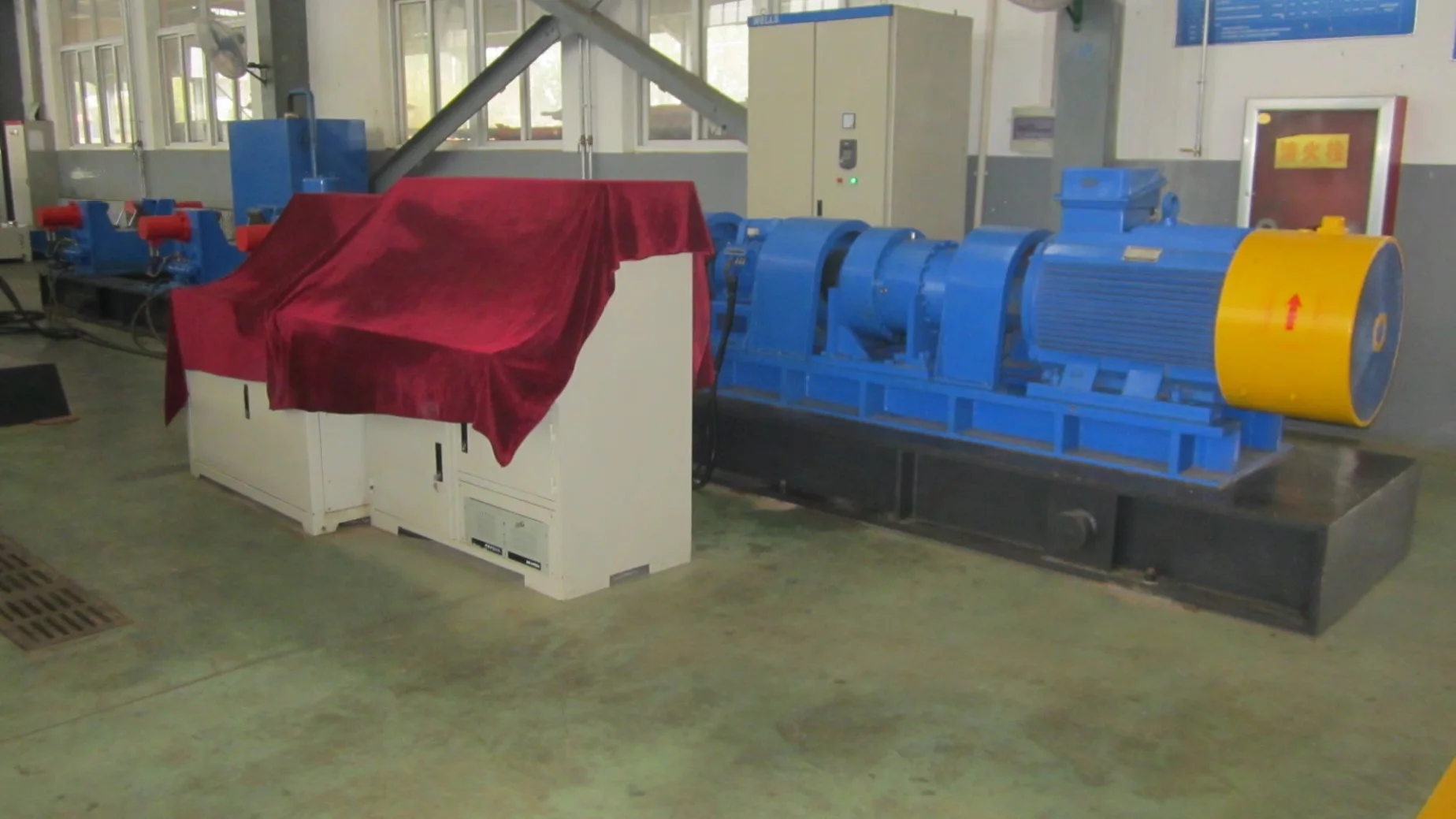

Power Section Testing Bench Downhole Motor Testing Bench

downhole drilling motor downhole drilling motor downhole

Your email address will not be published. Required fields are marked with *