Casing Section Mill bakeng sa ho Cheka Seliba sa Oli

CLICK_ENLARGE

Sistimi ea "Positive Stop" e tlase ho karolo ka 'ngoe ea leloala e tsitsisa mahare a sehang bakeng sa litekanyetso tse phahameng tsa ho kenella.

Lintho tse sehang tsa Tungsten Carbide li entsoe ka sebopeho sa "Polygon" mme li kenyelletsa "chip breaker" ho tlosa likhoele.

Lisebelisoa tsohle tsa leloala la karolo li entsoe ka lisebelisoa tsa tšepe tsa 4145 Aircraft Quality.

Moralo o bonolo le bonolo oa ho aha bocha ke tsona tse etsang hore karolo ena e fapane le tse ling kaofela.

Lebelo la ho sila le kaho ea nama ea nama e etsa hore ho be le leloala la likarolo le tla tsoa tlholisanong.

Moetso oa China oa li-casing section mill, The Section Mill For Casing ke sesebelisoa se hlokahalang bakeng sa lifensetere tse sililoeng ka har'a casing, e kopanyang mesebetsi ea ho seha le ho foma le ho sila. Sesebelisoa sa ho sila se kenngoa ka har'a casing e nang le lisebelisoa tsa ho cheka ho khaola casing sebakeng se boletsoeng. Ka mor'a hore casing e khaotsoe ka ho feletseng, casing e aroloa 'me e siloe ka ho toba ho tloha sebakeng sena. Ka mor'a ho fihla bolelele bo itseng, fensetere ea milled in casing e phethoa. Ka sebopeho se bonolo le ts'ebetso e bonolo, leloala la casing section ke sesebelisoa se sebetsang haholo bakeng sa ho kenya fensetere ka har'a casing. Ho feta moo, leloala la rona le ka petetsa samente selibeng se lahliloeng, e le hore samente e khone ho kopana le sebopeho sebakeng se selelele sa 360-degree. Samente e ka kena ka lithako tse teng le mapetsong a sebopeho ho koala polokelo. 'Me phello e molemo ho feta ho petetsa samente ka mor'a ho phunyeha.

Molao-motheo oa ho sebetsa: Ka mor'a ho silasesebelisoa se tsamaisoa hoboemo bo boletsoeng ka har'a casing e nang le sesebelisoa sa ho cheka, turntable ea qala, khatello ea pompo ea buloa, khatello e sutumelletsa piston ea sesebelisoa ho ea tlase, 'me khoune e tlas'a piston e sutumelletsa lehare ho bula le ho fokotsa leihlo le hlobotseng. . Ha lehare le buloa ho fihlela bophara bo boholo, ho fokotsa mahlo a hlobotseng ho phethoa. Lehare le ka buloa ka ho toba tlas'a phepelo ea khatello ea pompo e tsoelang pele, 'me leihlo le ka atolosoa ka ho toba ho ea tlaase. Ka mor'a hore pompo e emisoe, piston e tsosolosoa tlas'a ts'ebetso ea selemo, 'me lehare le tla huloa ka bohona.

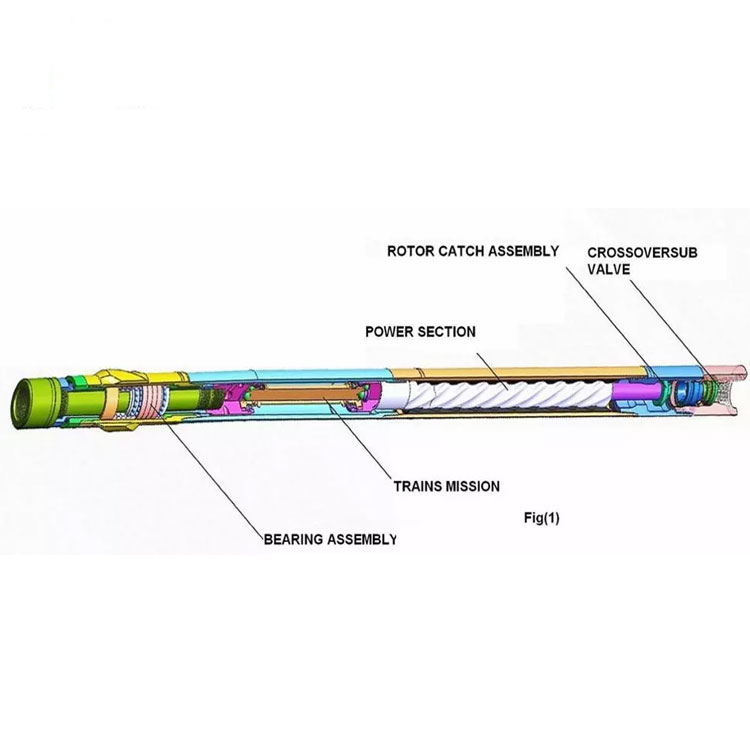

API Drilling Chinese Downhole Drilling Mud Motor ke mofuta oa sesebelisoa sa ho phunya likoti se tsamaisoang ke seretse. Seretse se tsoang pompong ea seretse se kena ka koloi ka tsela ea valve ea bypass, 'me ho theoha ha khatello pakeng tsa motlakase le ho tsoa ho etsoa, ho theoha ho joalo ho tla khanna koloi ea rotator ho potoloha,' me e fetise torque le lebelo la rotary ho bitana ka shaft ea universal le shaft ea phetisetso. . Thepa ea enjene ea downhole haholo-holo e ipapisitse le maemo a eona a thepa. Sehlahisoa sena se sebelisa theknoloji e phahameng le e ncha ea ho roala ho qoba ho roala li-rotor tse bakoang ke theknoloji ea setso. Matla a eona le bophelo ba eona li ntlafala haholo. E sebetsa ho Horizontal Directional Drilling, ho cheka ho kopantsoeng, liliba tsa lihlopha, liliba tse khelohang le ho sebetsa ha seliba, Ts'ebetso ea Coiled Tubing, joalo-joalo.dowhole phun motor

Downhole motor ke mofuta oa positive- displacement downhole motor(PDM).Kamora hore mokelikeli o chekang ka khatello e phahameng o kene ka har'a mochini oa "downhole" ho tsoa kutung ea ho phunya, khatello ea metsi e qobella rotor hore e fetisetse torque ho biting ho fihlela sepheo sa ho cheka.

Likopano tse fapaneng tse fapaneng tsa mochini o tlase bakeng sa boholo ba 1 7/8"~26" ka litlhaloso tse kholo tse 24 (tse khetholloang ka bophara ba ka ntle ba stator) : 1-11/16", 2-1/8", 2-3/8 ", 2-7/8", 3-1/8", 3-1/2", 3-3/4", 4", 4-1/8", 4-3/4", 5", 5-1/4", 5-7/8", 6-1/4", 6-1/2", 6-3/4", 7-1/4", 7-3/4", 8 ", 8-1/4", 8-1/2", 9", 9-5/8", 11-1/4".

Sebopeho sa sebopehoakarelletsaStraight, ho kobeha ho le mong, ho kobeha habeli, angle e fetolehang joalo-joalo. Thempereichara e hanyetsanang le mocheso e na le 250°F (120℃) kapa ka tlase ho 250℉ (120℃), le pakeng tsa 250 ℉(120℃) ho isa 355℉ (180℃). Hape re ka fana ka lintlha kaofela ho kenyeletsoaenjene e manganga seretse e thehiloeng ho oli le enjine e manganga metsi a letsoai a mangata.

Likarolo Tse Hlollang

Sekhahla sa ho potoloha le torque, bosebetsi bo phahameng haholo, phallo e pharalletseng, tšebetso e bonolo, ho lokisoa ha bonolo, botšepehi bo phahameng, bophelo bo bolelele ba tšebeletso.

Sireletsehile Kopo

Matla a lekaneng le lisebelisoa tse etselitsoeng ka ho khetheha tse ngata tse sa keng tsa senyeha ho netefatsa hore ho cheka ho sebetsa ka mokhoa o sireletsehileng.

Enjene e tlwaelehileng ya ho theosa e na le karolwana e latelang:

(1) Ho kopanya ha float kapa ho kopanya valve ea By-pass

(2) Kopano ea rotor e thibelang ho theoha

(3) Kopano ea karolo ea motlakase

(4) Kopano ea Universal shaft

(5) Kopano ea thepa

Ntle le enjene e tloaelehileng ea ho theosa, likarolo tse latelang ka morero o khethehileng lia fumaneha ho etsa enjene e ka theolehang ho fihlela litlhoko tse fapaneng tsa tšebetso ea ho cheka:

(1) Motsoako oa tataiso

(2) Kobello (e kentsoeng ka holimo kapa ka tlaase ho tsela

valve ho etsa enjene e le 'ngoe kapa e habeli e kobehang fatše)

(3) Karolo ea motlakase e se nang letho

(4) Bolulo bo Felletseng ba Bend (ka 0~3° angle e tsitsitseng)

(5) Ntlo e ka feto-fetohang

(6) Setsi sa Bolulo sa Bolulo mabapi le kopano

(7) Setsi se feto-fetohang

mochini oa ho phunya ka tlase

(Mehlala e meng e teng bakeng sa litšupiso tsa hau, mefuta e mengata le li-deatils pls ikopanye le rona.)

(Ehlile, ho itlhophisa le hona ho lumelletsoe, ha feela o ka fana ka setšoantšo se qaqileng, haholo likarolo tse ling joalo ka li-bearings.)

Enjene e 'ngoe le e 'ngoe ea seretse se ka tlaase e lekoa bencheng ea profeshenale ea ho etsa liteko 'me enjene ea seretse se ka tlaase e tiisitsoe ka 100%, 'me u tla fuoa tlaleho ea tlhahlobo.

Enjene e 'ngoe le e' ngoe ea seretse se theohileng e ka tsoela pele ho sebetsa matsatsi a 7 ~ 10 ka boemo bo botle ba ho sebetsa le ts'ebetso e nepahetseng.

Ehlile, tšebeletso ea ka mor'a thekiso ea inthanete e fumaneha ka nako efe kapa efe.

Mofuta | 5LZ73 7.0 | 5LZ89 7.0 | 5LZ95 7.0 | 7LZ95 3.5 | 9LZ95 7.0 | 5LZ120 7.0 | |

Boholo ba lesoba | Mm | 95~121 | 114~152 | 118~152 | 118~152 | 118~152 | 149~200 |

In | 33/4~43/4 | 41/2~6 | 45/8~6 | 45/8~6 | 45/8~6 | 57/8~77/8 | |

Mofuta oa Khoele | Holimo | 23/8"REG | 23/8"REG | 27/8"REG | 27/8"TBG | 27/8"REG | 31/2"REG |

Tlase | 23/8"REG | 23/8"REG | 27/8"REG | 27/8"REG | 27/8"REG | 31/2"REG | |

Khatello ea molomo e theoha | Mpa | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~3.5 | 1.4~7 | 1.4~7 |

Khothalletsa Phallo | L/S | 3~8 | 3~8 | 7~12 | 7~11 | 6~10 | 9~14 |

Rotary e nyane | R/Mots | 109~291 | 95~200 | 90~195 | 120~240 | 90~200 | 95~200 |

Khatello ea motlakase e theoha | Mpa | 2.4 | 2.4 | 3.2 | 2.4 | 2.4 | 3.2 |

Torque e sebetsang | N.M | 460 | 628~838 | 1260~1630 | 723~960 | 750~1020 | 1480~1820 |

Torque e salang | N.M | 650 | 1300 | 2200 | 1500 | 1550 | 2440 |

Matla a hlahisang | KW | 4.7~12.5 | 7.3~15.3 | 13.6~29.5 | 18~24 | 8.3~18.5 | 16.4~34.5 |

E khothalelitsoeng boima ba 'mele | T | 4.7~12.5 | 2.0 | 2.5 | 1.0 | 2.5 | 3 |

Max bit boima | T | 2.5 | 3.0 | 5 | 1.5 | 5 | 5 |

Bolelele | Setereiti | 3450 | 3570 | 4450 | 2500 | 3590 | 5085 |

Mokokotlo o le mong | 3450 | 4675 | 3590 | 5335 | |||

Boima ba 'mele | Setereiti | 100 | 98 | 140 | 89 | 120 | 390 |

Mokokotlo o le mong | 102 | 150 | 120 | 420 | |||

Mofuta | 5LZ165 7.0 | 5LZ165 7.0 | 5LZ172 7.0 | 5LZ197 7.0 | 5LZ210 7.0 | 5LZ244 7.0 | |

Boholo ba lesoba | Mm | 213~251 | 213~251 | 213~251 | 251~311 | 251~375 | 311~445 |

In | 83/8~97/8 | 83/8~97/8 | 83/8~97/8 | 97/8~121/4 | 97/8~143/4 | 121/4~171/4 | |

Mofuta oa khoele | Holimo | 41/2"REG | 41/2"REG | 41/2"REG | 51/2"REG | 65/8"REG | 65/8"REG |

Tlase | 41/2"REG | 41/2"REG | 41/2"REG | 65/8"REG | 65/8"REG | 75/8"REG | |

Khatello ea molomo e theoha | Mpa | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~7 | 1.4~7 |

Khothalletsa Phallo | L/s | 20~28 | 20~28 | 25~35 | 25~57 | 35~50 | 50~75 |

Rotary e nyane | R/mots | 90~160 | 80~150 | 90~160 | 86~196 | 100~160 | 100~160 |

Khatello ea motlakase e theoha | Mpa | 2.4 | 3.2 | 4.0 | 4.0 | 4.0 | 4.0 |

Torque e sebetsang | N.m | 2750~3960 | 3860~4980 | 5860~6970 | 7800~9350 | 9980~11900 | 12870~13970 |

Torque e salang | N.m | 6300 | 8470 | 11550 | 18690 | 19600 | 23000 |

Matla a hlahisang | Kw | 31.6~56.2 | 37~69.4 | 60.4~107.4 | 70~160 | 115~183 | 140~225 |

E khothalelitsoeng boima ba 'mele | T | 8 | 8 | 10 | 16 | 17 | 18 |

Max bit boima | T | 16 | 16 | 16 | 24 | 28 | 30 |

Bolelele | Setereiti | 5930 | 6830 | 7230 | 8470 | 8400 | 9060 |

Mokokotlo o le mong | 6180 | 7080 | 7480 | 8720 | 8660 | 9320 | |

Boima ba 'mele | Setereiti | 742 | 820 | 930 | 1140 | 1460 | 1980 |

Mokokotlo o le mong | 772 | 850 | 970 | 1195 | 1520 | 2050 | |

Karolo ea Matla:

Sesebelisoa sa Anti-dropping

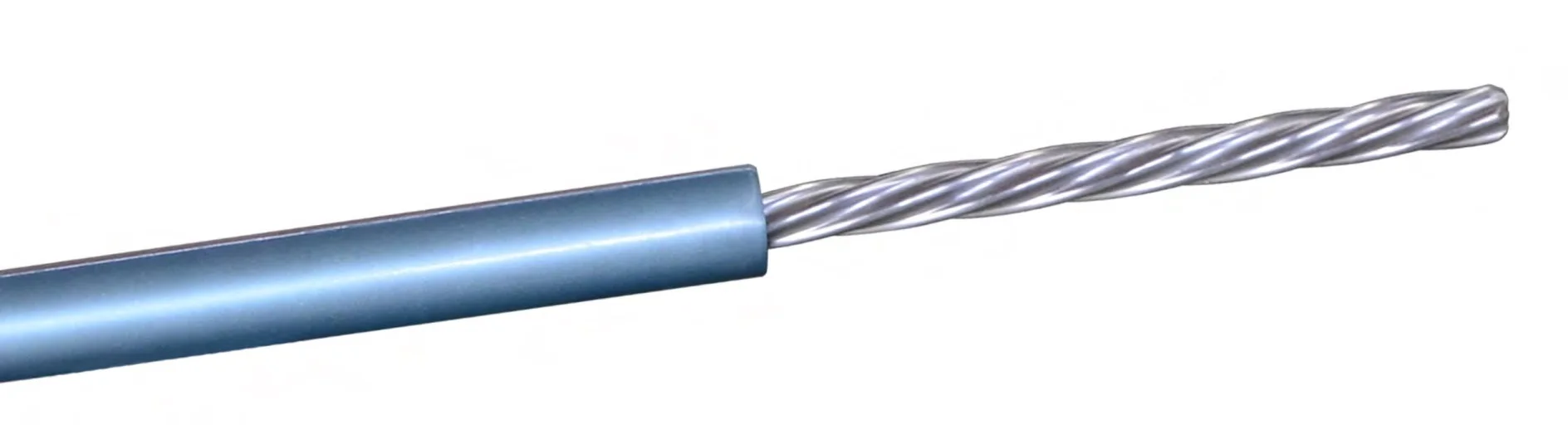

Ball Drive Universal Shaft Assy

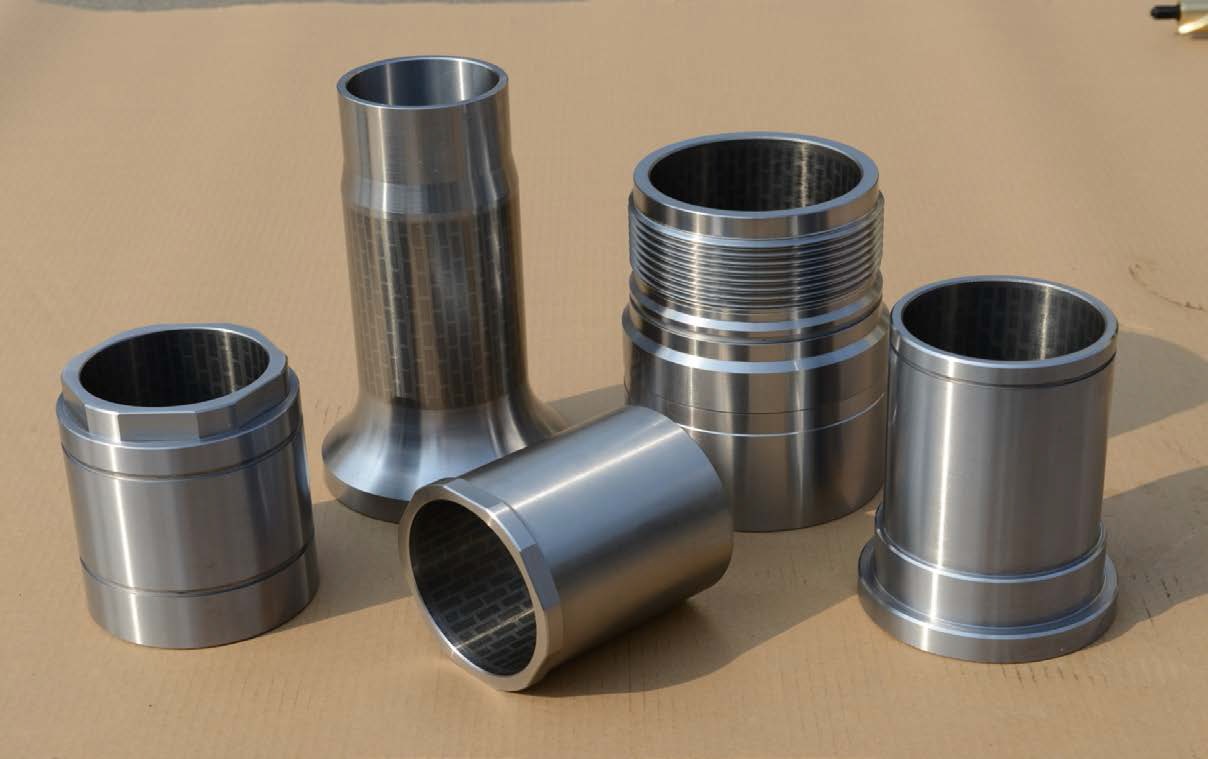

ABH Assy

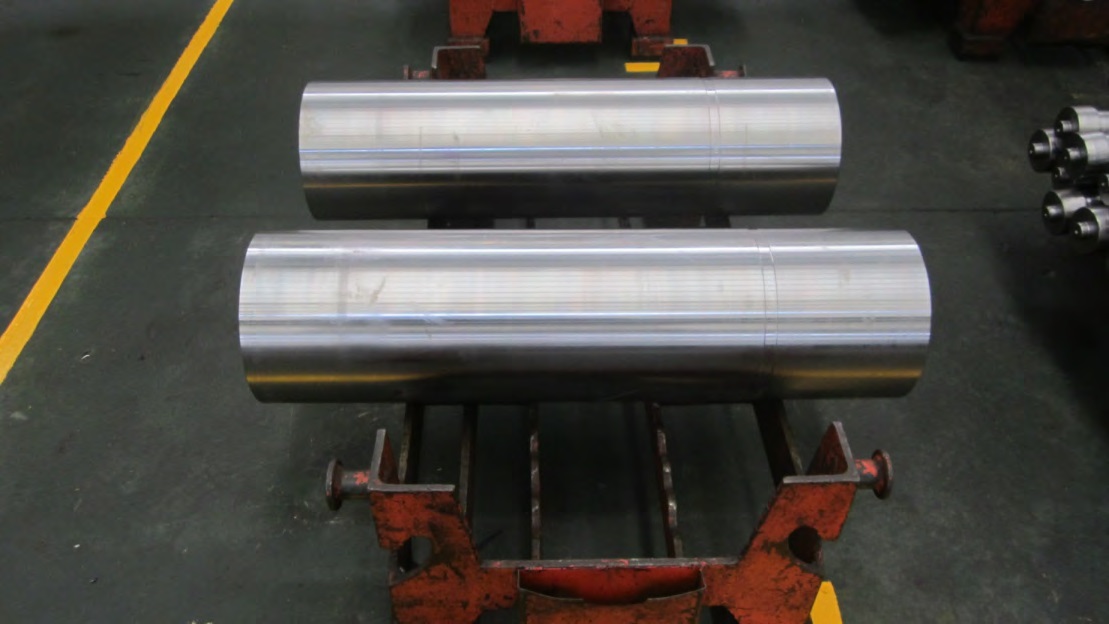

Driveshaft Mandrel Finished TC Radi

E felile Houbina Transmission Shaft Assy

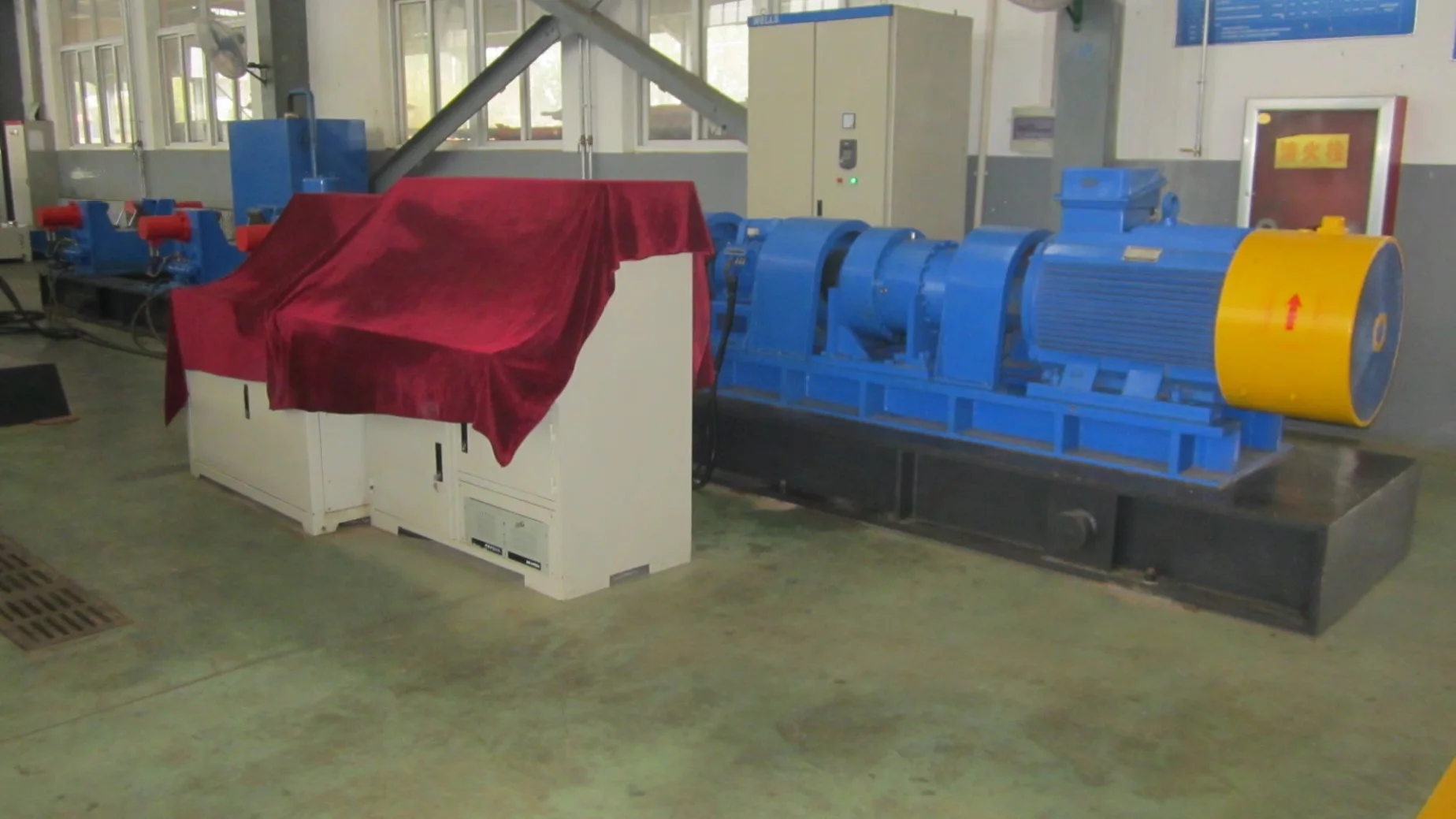

Bench ea ho Lekola Karolo ea Matla Bench ea Downhole Motor Testing

ho phunya mochini oa ho phunya lithunya tse tlase

Aterese ea hau ea lengolo-tsoibila e ke ke ea phatlalatsoa. Libaka tse hlokahalang li tšoailoe ka *